Power Distribution Box Manufacturer: Leading Solutions for Industrial Electrical Systems

2026-01-09

Imagine an industrial electrical system running smoothly, efficiently—without a glitch. At the heart of this reliability lies a crucial component: the power distribution box. As a foundational element, it ensures safe and organized electricity flow, preventing downtime and boosting productivity. In a market filled with options, one name stands out for innovation and excellence: Lugao. As a leading manufacturer, Lugao crafts precision-engineered solutions tailored to meet the demanding needs of industrial environments. This blog will explore how Lugao's cutting-edge power distribution boxes are revolutionizing electrical systems, offering insights into their design, benefits, and real-world applications. Stay tuned to uncover what makes Lugao a trusted partner for industries worldwide!

Innovative Power Distribution Box Designs for Industrial Safety

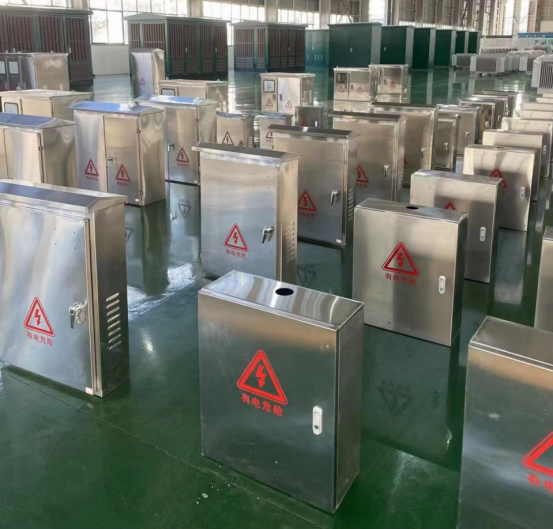

Modern industrial settings demand power distribution solutions that go beyond basic functionality, prioritizing worker safety and operational reliability. Innovative power distribution box designs are emerging to address these needs, featuring robust enclosures made from materials like corrosion-resistant steel or reinforced plastics that withstand harsh environments. These boxes often incorporate advanced locking mechanisms and tamper-proof seals to prevent unauthorized access, reducing the risk of electrical accidents. Additionally, intuitive labeling systems and color-coded wiring help technicians quickly identify circuits, minimizing errors during maintenance or emergencies.

Beyond physical durability, cutting-edge designs integrate smart technologies for real-time monitoring and control. For instance, some power distribution boxes now include embedded sensors that track temperature, humidity, and load fluctuations, alerting personnel to potential hazards like overheating before they escalate. This proactive approach enhances safety by enabling early intervention, while wireless connectivity allows remote management from control rooms. Such innovations not only protect workers but also boost efficiency by reducing downtime caused by electrical failures.

To stand out in the industrial sector, manufacturers are customizing these boxes to meet specific safety standards and user needs. Modular designs offer flexibility, allowing components like circuit breakers or surge protectors to be easily swapped or upgraded without extensive rework. Ergonomic features, such as angled displays for better visibility and insulated handles, further enhance usability in high-risk areas. By blending durability, intelligence, and adaptability, these innovative power distribution boxes set a new benchmark for industrial safety, ensuring that power management aligns with modern workplace demands for protection and performance.

Customizable Solutions in Electrical Power Management

In the realm of electrical power management, one size rarely fits all—every facility, from a bustling data center to a remote wind farm, has unique energy needs and constraints. Customizable solutions step in to bridge this gap by offering tailored approaches that can be fine-tuned for specific operational demands, budget considerations, or sustainability goals. By leveraging advanced software and hardware integrations, these solutions allow users to dynamically adjust power distribution, monitor consumption in real-time, and optimize efficiency without a costly overhaul. This flexibility not only enhances reliability but also paves the way for future scalability as needs evolve, making it a practical choice for industries aiming to stay agile in a fast-changing energy landscape.

What truly sets these customizable approaches apart is their ability to integrate seamlessly with existing infrastructure, whether it's retrofitting an older building or embedding smart controls into new construction. Through modular components and adaptable interfaces, power management systems can be configured to prioritize areas like load balancing, backup power readiness, or renewable energy integration—all from a user-friendly dashboard. This hands-on customization empowers operators to tackle issues like peak demand charges or voltage fluctuations proactively, reducing downtime and operational costs while ensuring compliance with local regulations or green initiatives. It's this blend of precision and adaptability that transforms basic power handling into a strategic asset for businesses.

Beyond mere technical tweaks, customizable solutions in electrical power management foster innovation by encouraging a collaborative design process between engineers and end-users. Instead of settling for off-the-shelf packages, organizations can co-create systems that reflect their specific workflows, such as prioritizing critical circuits in a hospital or automating shutdowns in a manufacturing plant during off-hours. This iterative, problem-solving mindset leads to more resilient and intuitive power networks that not only meet today's challenges but also anticipate tomorrow's shifts, from grid decentralization to electrification trends. In essence, it's about crafting a power management strategy that feels uniquely yours, driving both performance gains and peace of mind.

Advanced Materials Enhancing Durability in Harsh Environments

In the relentless pursuit of resilience, advanced materials have emerged as game-changers, specifically engineered to withstand extreme conditions that would rapidly degrade conventional options. These innovations, such as high-performance ceramics and metal matrix composites, leverage unique properties like exceptional hardness, corrosion resistance, and thermal stability, enabling structures and machinery to operate reliably in environments ranging from scorching industrial furnaces to frigid arctic expeditions. By pushing the boundaries of material science, researchers are not only extending the operational lifespans of equipment but also reducing maintenance costs and safety risks, making harsh settings more manageable and sustainable over time.

One standout example is the development of superalloys, which are tailored to retain strength and resist oxidation at temperatures exceeding 1000°C, critical for aerospace and power generation applications. Unlike earlier materials that might fail under such thermal stress, these alloys combine elements like nickel, cobalt, and chromium in precise formulations, often enhanced through advanced manufacturing techniques like additive production. This allows for the creation of components that endure prolonged exposure without significant wear, ensuring that aircraft engines and gas turbines maintain peak performance even in the most punishing thermal cycles, thereby boosting overall efficiency and reliability.

Beyond thermal extremes, advanced materials also address corrosive challenges in marine and chemical processing environments through innovations like graphene-reinforced polymers and self-healing coatings. These materials actively fight degradation by forming protective barriers or repairing micro-cracks autonomously, which prevents the slow erosion that often leads to catastrophic failures. As industries increasingly adopt these solutions, they gain a competitive edge by minimizing downtime and environmental impact, showcasing how material advancements are not just about surviving harsh conditions but thriving in them, paving the way for more durable and adaptable technologies across diverse sectors.

Efficient Energy Distribution Systems for Modern Industries

Modern industries are increasingly adopting sophisticated energy distribution systems that go beyond mere power supply, focusing on optimizing resource allocation to enhance operational efficiency and reduce environmental impact. These systems integrate cutting-edge technologies such as smart grids and real-time monitoring to dynamically manage energy consumption across facilities. By leveraging predictive analytics, they can anticipate peak demand periods and adjust distribution accordingly, minimizing waste and improving cost-effectiveness.

Innovations in energy storage, like advanced battery solutions and thermal storage units, are transforming how industries handle energy distribution, allowing for smoother integration of renewable sources such as solar and wind. This not only supports sustainability goals but also bolsters operational resilience by reducing dependency on traditional, fluctuating power grids. Industries can thus maintain consistent productivity even during energy shortages or disruptions.

Beyond technical upgrades, the shift towards decentralized energy networks empowers manufacturing plants and other industrial sites to generate and share energy locally, fostering greater independence and collaboration. This approach not only cuts transmission losses but also encourages a circular economy mindset, where waste heat or excess energy is repurposed, leading to more holistic and adaptable industrial ecosystems.

Smart Technology Integration in Electrical Control Panels

Incorporating smart technology into electrical control panels unlocks a new realm of efficiency and communication within industrial and commercial settings. Gone are the days of static, isolated systems; today's panels can communicate seamlessly with other devices and networks. This integration enables real-time data collection on energy consumption, equipment performance, and operational status, allowing operators to monitor and adjust processes remotely through intuitive interfaces. By embedding sensors and connectivity modules directly into the panel design, these systems provide immediate insights that can preempt failures, reduce downtime, and optimize resource use, transforming simple control units into proactive management tools.

What sets advanced smart control panels apart is their ability to adapt and learn from operational patterns. Leveraging technologies like IoT (Internet of Things) and edge computing, these panels analyze incoming data locally to make autonomous decisions, such as adjusting power loads or triggering maintenance alerts without human intervention. This not only enhances safety by minimizing manual handling in hazardous environments but also boosts productivity through predictive analytics. For example, an integrated panel might identify a motor's unusual vibration patterns and automatically schedule a maintenance check, preventing costly breakdowns. Such capabilities shift the focus from reactive fixes to strategic, data-driven operations, making facilities more resilient and cost-effective.

Beyond internal functions, smart integration facilitates broader system coordination and sustainability goals. Panels can now interface with building management systems, renewable energy sources, or cloud platforms to synchronize operations across entire facilities. This connectivity supports energy conservation by dynamically balancing loads based on real-time demand or integrating with solar panels to maximize green energy usage. Additionally, smart panels contribute to regulatory compliance by maintaining detailed logs and reports that simplify audits. In essence, this technology turns control panels into central hubs for innovation, enabling businesses to stay agile in a rapidly evolving technological landscape while achieving significant operational and environmental benefits.

Expert Engineering Support for Reliable Power Infrastructure

In today's fast-paced world, a reliable power infrastructure isn't just a convenience—it's the backbone that keeps everything running smoothly. When engineers tackle these complex systems, they're not merely fixing problems; they're crafting solutions that stand the test of time. Imagine having a team of seasoned professionals who dive deep into every detail, ensuring that from the grid to the generator, every component works in perfect harmony.

What sets expert engineering support apart is its tailored approach. Instead of one-size-fits-all fixes, specialists analyze the unique challenges of each site, whether it's a bustling urban center or a remote industrial facility. They leverage cutting-edge technology and decades of hands-on experience to preempt potential issues, minimizing downtime and boosting efficiency. It's like having a silent guardian for your power network, always vigilant and ready to adapt.

Beyond technical prowess, this support fosters innovation and sustainability. Engineers don't just maintain what's there; they envision what could be, integrating renewable energy sources and smart systems for a resilient future. By prioritizing long-term reliability over quick fixes, they help businesses and communities thrive, ensuring that the lights stay on and the machinery hums without a hitch.

FAQ

Industrial environments often require boxes that can withstand harsh conditions like dust, moisture, and high temperatures. Reputable manufacturers address this by using durable materials such as stainless steel or polycarbonate, and rigorous testing to ensure long-term reliability.

Top manufacturers integrate features like smart metering, modular components for optimized power flow, and efficient cooling systems to reduce energy loss, helping industries cut operational costs and meet sustainability goals.

Customization can range from tailored sizes and mounting configurations to specialized safety features like arc fault detection or compatibility with renewable energy sources, allowing seamless integration into unique systems.

Manufacturers typically ensure compliance with international standards such as IEC 61439, UL 508A, and NEMA ratings, which cover aspects like insulation, grounding, and protection against electrical hazards for safe operation.

They implement corrosion-resistant coatings, sealants, and materials like powder-coated steel or fiberglass, along with regular quality checks to prevent degradation and extend product life.

Trends include IoT connectivity for remote monitoring, predictive maintenance capabilities, and integration with renewable energy grids, enabling smarter, more resilient power management in factories and plants.

Yes, many offer modular designs that allow easy expansion by adding new sections or upgrading components without major downtime, supporting growth and flexibility in operations.

Support often includes installation guidance, maintenance services, access to spare parts, and technical assistance to troubleshoot issues, ensuring continuous system reliability and customer satisfaction.

Conclusion

Leading power distribution box manufacturers specialize in creating tailored solutions for modern industrial electrical systems, ensuring safety and efficiency across diverse applications. By offering innovative designs and customizable power management systems, they address the unique demands of various industries, from manufacturing plants to energy facilities. Their approach combines advanced materials that enhance durability in harsh environments with efficient energy distribution systems, optimizing performance while minimizing risks. This focus on adaptability and robustness helps maintain operational continuity even under challenging conditions, supporting industries in achieving higher productivity standards.

Integration of smart technology into electrical control panels further elevates these solutions, enabling real-time monitoring and automated adjustments for improved reliability. Manufacturers provide expert engineering support to build and maintain robust power infrastructure, ensuring systems are resilient and future-proof. By merging technical expertise with cutting-edge innovations, they deliver comprehensive packages that not only meet current industrial needs but also anticipate upcoming trends, fostering sustainable growth and enhanced safety protocols in electrical management worldwide.

Contact Us

Contact Person: Doreen

Email: [email protected]

Tel/WhatsApp: 8618057712366

Website: https://www.liugaopower.com/